Non-Conventional Fibres Association Urges Maha Govt. To Include Machines Specific To NCF In New Textile Policy

The newly formed Non-Conventional Fibres Association (NCFA), with its aim of promoting the production and consumption of sustainable, non-conventional fibres, has made a strong representation to the government for addressing some of the obvious omissions in the textile policies and schemes that have been holding back the adoption of these fibres in mainstream textile industry in India.

NCFA team – Aditya Mody – President, S.K. Gupta – Vice President, Dr G.S. Nadiger – General Secretary – met with the Textiles Secretary, Government of Maharashtra, to give their recommendations for the new Maharashtra State Textile Policy 2023-28.

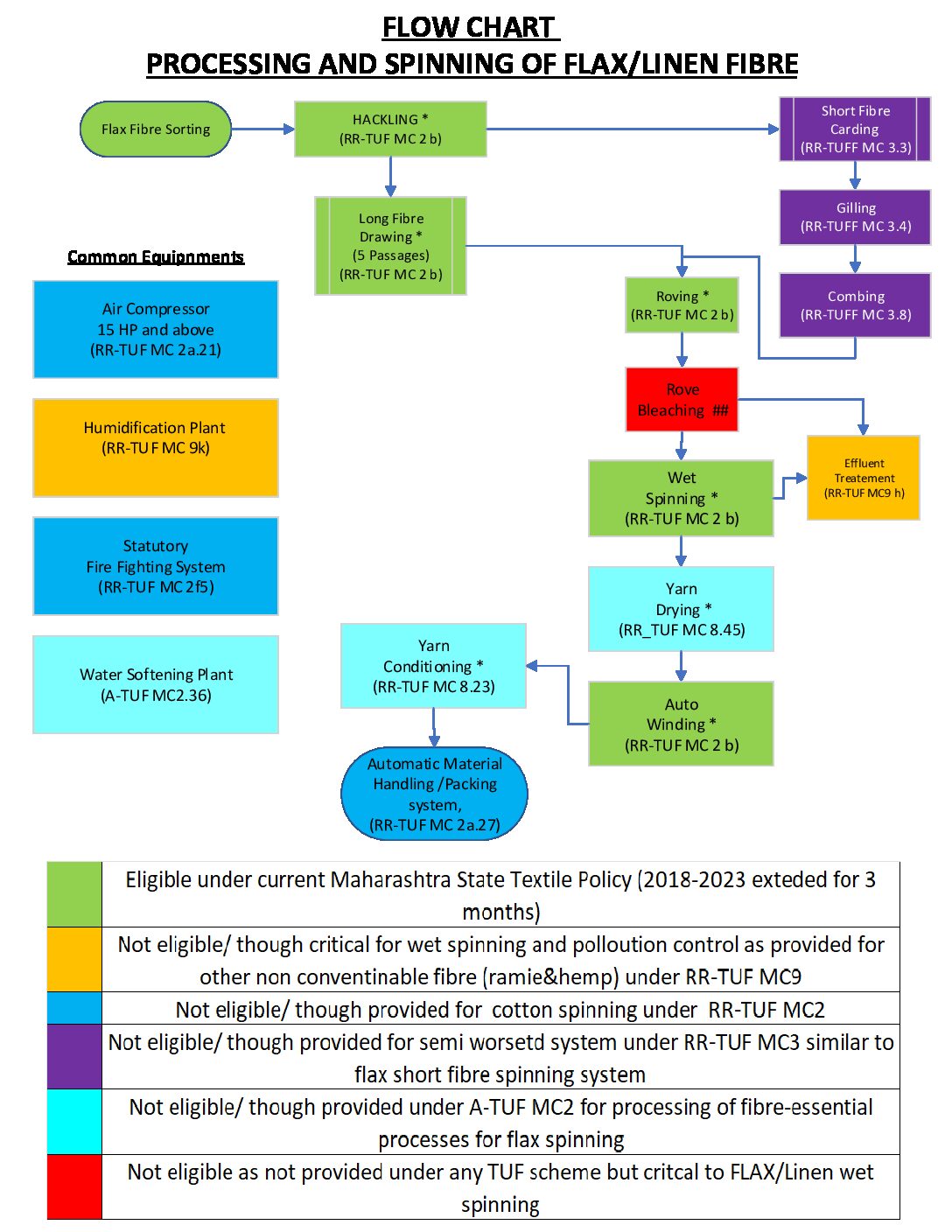

NCFA underlined the need for publishing the list of machines specific to the processing and wet spinning of flax/linen (which comes under non-conventional fibres). According to Aditya Mody, “These machines are either completely missing, or appear under inapplicable chapters, in both the RR-TUF and A-TUF schemes for capital subsidy under the current Textile Policy 2018-23, thus making these machines ineligible for the subsidy.”

The NCFA has identified 12 machines that miss out on the capital subsidy. “We have requested the ministry to introduce the appropriate clause for listing these additional machines specific to processing and wet spinning of non-conventional fibres,” said Mody.

The Indian government has adopted a `Focus Fibre Focus State’ (FFFS) approach for development of sustainable, natural fibres in the country. Tamil Nadu has been identified for banana fibre development, Tripura for pineapple fibre, Orissa for sisal fibre, Uttarakhand for hemp/nettle and Madhya Pradesh for flax.

“We have pointed out that Maharashtra has the potential to develop all these natural fibres too. In fact, the Maharashtra State Textiles Policy (2017-2023) had thus stipulated the above class of fibres as `non-conventional fibres’ for planned development,” he stated.

According to research on flax fibre by NCFA, from 2022 onwards, Asia has begun playing an important role in flax fibre investments worldwide, even as Europe remains a leader in flax fibre production. Surprisingly, Ethiopia too is emerging an important player in flax fibre.

Flax/linen is the most widely used of non-conventional fibres in the global textile and clothing industry. Fortunately, other non-conventional fibres too are garnering the attention of the industry.

Says Aditya, “Last year I planned to set up a spinning unit for non-conventional fibres but faced some policy level impediments. While there are organisations dedicated to promoting specific fibres, there is none that actually promotes all non-conventional fibres and their applications. That made me think about the need for an organisation like NCFA to deal with issues related to the non-conventional fibre industry and promote its applications. NCFA symbolises the coming of age of the non-conventional fibre industry.”

Said S.K. Gupta, Vice-President of NCFA, and a textile industry veteran, “Formation of NCFA couldn’t have been more timely as it coincides with the accelerated global pursuit for environmental protection and sustainability. I am confident that this association would be instrumental in developing and growing this sector as enshrined in its statement of objectives.”

Said Dr. Nadiger, “Awareness of, and demand for non-conventional fibres is inching ahead. These non-conventional fibres can help the textile industry become more sustainable, while effectively utilising the agro byproducts. Moreover, most of these fibres have inherent functional properties, doing away with the need for chemical applications. The NCFA is a platform for like-minded people with a vision to harness the advantages of these fibres.”

One of NCFA’s main objectives is to promote and grow production and consumption of non-conventional, plant-based fibres, and to support all initiatives that pursue similar mission. NCFA will work closely with other associations and organisation for the same, and more importantly with the agriculture sector and research institute to develop quality fibres and testing facilities.